sinowares

sinowares  August 21,2025

August 21,2025

Medical needle tube micro-imaging design can effectively solve the accuracy of image targeting under ultrasound surgery. In many minimally invasive punctures or other minimally invasive surgeries, the demand for contrast imaging and the variety of contrast modalities are increasingly high. In contrast imaging technology, what is the need to break through this hard indicator?

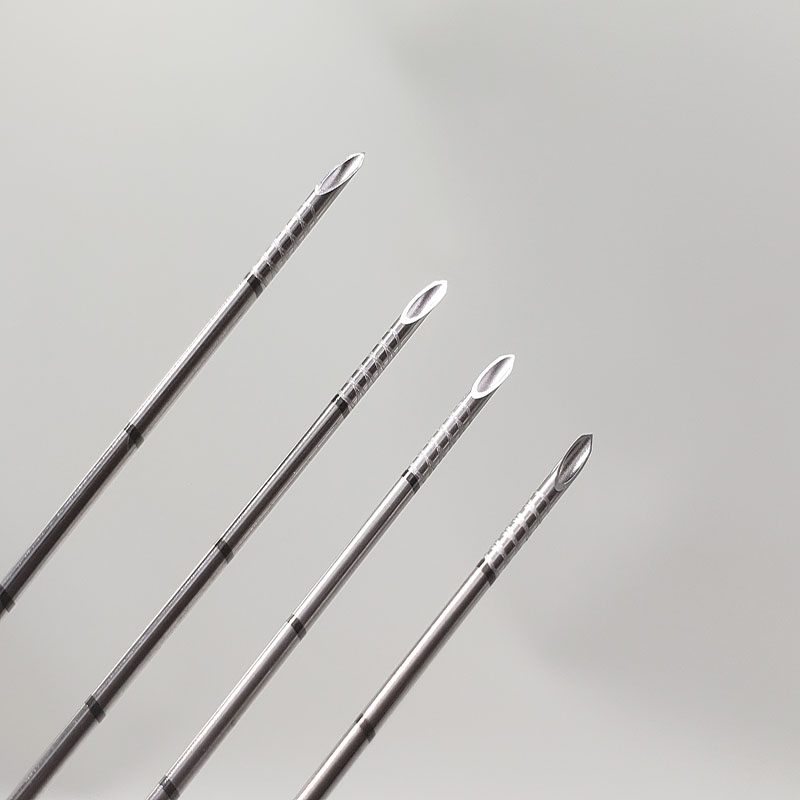

First of all, we understand the status of the design and implementation of micro-thin needle tubes. The minimally invasive needle tubes are small and ultra-thin, with diameters between 0.5MM-2.5MM and wall thicknesses between 0.05MM and 0.1MM. Of course, it is necessary to realize a multi-shaped angular geometric state to distinguish the accuracy of the doctor's targeting during surgery

Due to the current domestic manufacturing technology, we temporarily stop at ordinary imaging such as frosted modeling. The process can barely meet the needs of domestic technology, but if we keep up with the pace of advanced foreign imaging technology, it can be said that there is still a certain distance. Technology set: "The advantages of diversification of geometric shapes, smooth geometric mirrors, consistency of geometric rules, consistency of geometric curves, etc." are favored and selected by major doctor users in the world.

SINOWARES multi-axis imaging equipment R&D technology breakthrough, it can be said to be a high-quality patch of minimally invasive needle tube imaging technology, a diversified choice of fine thin-walled needle tube imaging design links, providing more creative design space, the device is intelligently driven at multiple latitudes Under the link, it can achieve zero-angle to N-angle type, diamond shape, semi-circular shape, etc. at high speed. Its function: It does not change the thickness of the tube wall, the strength of the tube body, the degree of the needle tube, the composition of the needle body, the smoothness, it must effectively reduce the friction, reach the minimum liquid state, and completely change the blank of domestic technology. The goal is to continue to optimize the technical defects in the fastest time and reach the optimal degree of demand.

The imaging design of minimally invasive microneedles needs to be designed more safely, smoothly, with contrast, stability, and clearness. The SINOWARES team will, as always, provide more quality implementation solutions in the imaging process of microneedles And look forward to working with more designers to help the minimally invasive device industry improve and realize the mission of more structural supporting technologies.