sinowares

sinowares  August 21,2025

August 21,2025

In the field of minimally invasive instrument surgery, the puncture device involves many links in the field of surgery. When it comes to puncture, what are the places we need to pay attention to when designing and manufacturing? Let's discuss it together!

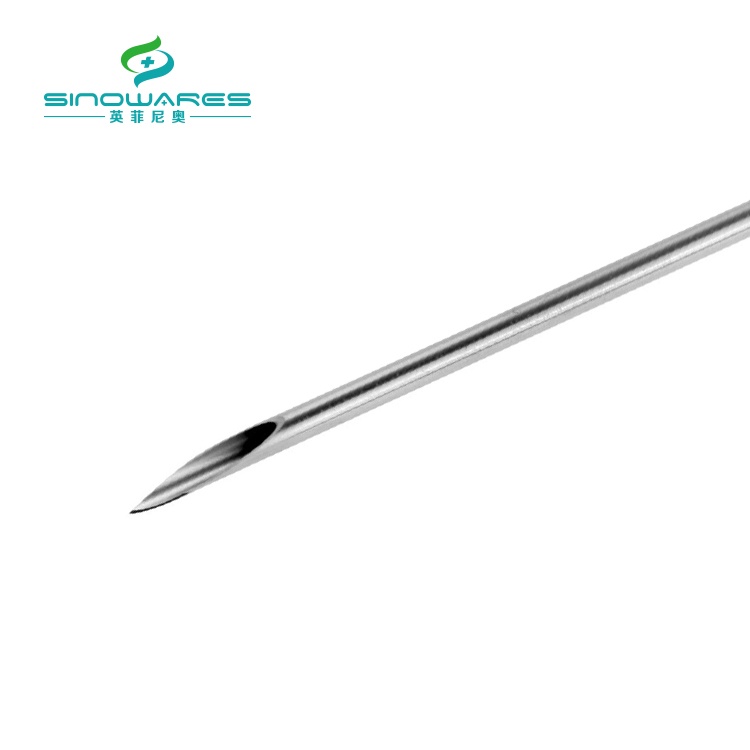

First of all, it is the positioning of product use and quality. Whether the puncture needle can successfully puncture the skin, whether it can successfully take tissue or inject drugs, the cutting edge of the puncture needle plays a vital role. The edge of the puncture needle affects the strength of the puncture needle. The edge angle and structure directly affect the puncture force effect. In the structure of the blade surface, special attention must be paid to the angle requirement, as well as the roughness of the blade surface and the thickness of the blade surface. The solid inner needle will select the tip of Mitsubishi, but the length will affect the puncture. It may be interrupted during the use and left in the tissue. If the doctor does not notice the needle drop, it may cause infection.

Second, it is the hardness of the puncture needle. Hardness is the most basic guarantee to ensure the continuous use of puncture force. Therefore, we design the material puncture hardness here. We must set the parameters with the best hardness under the condition of ensuring straightness. Generally, our hardness should be designed in HV360-420. between.

Finally, it is the choice of materials. Generally, the material of the puncture has a very large relationship with the roughness of the material. The roughness of the material we need to choose is about Ra0.4.The surface roughness of the inner core also needs to be within Ra0.4. Of course, the roughness and toughness of materials imported from Japan, Korea, and the United States will be relatively better than those made in China. Because of the influence of other factors, the price will be more expensive than domestic materials. Therefore, the quality positioning of the product is very important.